Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

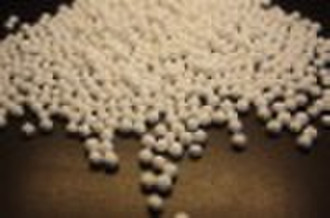

Claus Catalyst

Kalila Deng

Contact person

Basic Information

| CAS No. | 13463-67-7 |

|---|---|

| Other Names | Catalyst |

| Purity | 85% |

| Place of Origin | Jiangxi China (Mainland) |

| Brand Name | Pingxiang Petrochemical |

Claus Catalyst Claus catalyst are considered the industry standard for delivering improved sulfur recovery.They are used as sulfur recovery catalysts in natural gas plants,refineries,and smelter.They perform well in facilities that employ Claus process plants,as well as other types of sulfur recovery plants.These spherical activated aluminas and titania-based catalysts have high surface area and purity,low bulk density and high macroporosity.These properties ensure maximum activity for the conversion of sulfur compounds. Two main types of catalysts are used in conventional Claus units: activated alumina;and titania catalyst.They vary in their capability to hydrolyze COS and CS2 and to resist poisoning(sulfation).These Claus catalysts may be used alone or in combination beds, depending upon performance requirements.Technical Specification ItemPSR-1PSR-21PSR-31PSR-41PSR-51Size&Shape(mm)Φ4-6BallsΦ4-6BallsΦ4*5-15PelletΦ4-6BallsΦ3*4-15TrifoliumColorWhiteWhiteWhiteBrownBlueMain contentsAl2O3≥93Na2O≤0.3Al2O3≥85TiO2 3-6TiO2≥85Al2O3≥80FeO≥6CoO 2.5-3.0MoO3 10-11Bulk density(g/ml)0.65-0.720.72-0.750.85-1.00.70-0.820.65-0.80Active surface(m2/g)≥300≥260≥100≥260≥200Pore volume(ml/g)≥0.4Crushing strength N≥150≥140≥100≥140≥160Abrasion loss %≤0.3≤0.3≤1≤0.3≤1.0Major functionUniversal catalyst for fulfur recovery in acid gasWith high hydrolysis and conversion of COS and CS2Catalyst with high sulfate resistance and conversionCatalyst with protection of oxygen leakageCatalyst for Tail gas hydrotreating

Delivery terms and packaging

Packaging Detail: 25kg plastic bags or MT BAG on pallet Delivery Detail: Within 7days for one 20ft container

Port: Shanghai,Qingdao,Shenzhen

Payment term

Documents Against Acceptance

Documents Against Payment

Letter of credit

Telegraphic transfer

MoneyGram

Western Union

-

Payment Methods

We accept: